The rubber conveyor has the characteristics of heat-resistant belt, wear-resistant belt, burn-resistant belt, oil-resistant belt, alkali-resistant belt, alkali-resistant belt, heat-resistant belt, and cold-resistant belt. Mainly used in the transportation of solid materials in various mining, metallurgy, steel, coal, hydropower, building materials, chemical, food and other enterprises.

Conveyor belt is the main part of belt conveyor. It is mainly used for large-scale continuous transportation in coal, mining, metallurgy, chemical, construction and transportation sectors. The transported materials are divided into blocks, powders, pastes and pieces. Items etc. From the perspective of microscopic structure, the conveyor belt is mainly composed of three parts: skeleton material, covering layer and bottoming material. The covering layer is the key part that determines its performance and use. According to the different materials used in the covering layer, the conveyor belt industry can be divided into two categories: heavy conveyor belts and light conveyor belts. The former uses rubber (including natural rubber and synthetic rubber) as the main raw material, so it is also called rubber conveyor belts. The scope is concentrated in the fields of heavy industry and infrastructure construction; the shells mainly use polymer materials, which are mainly used in light industrial fields such as food and electronics.

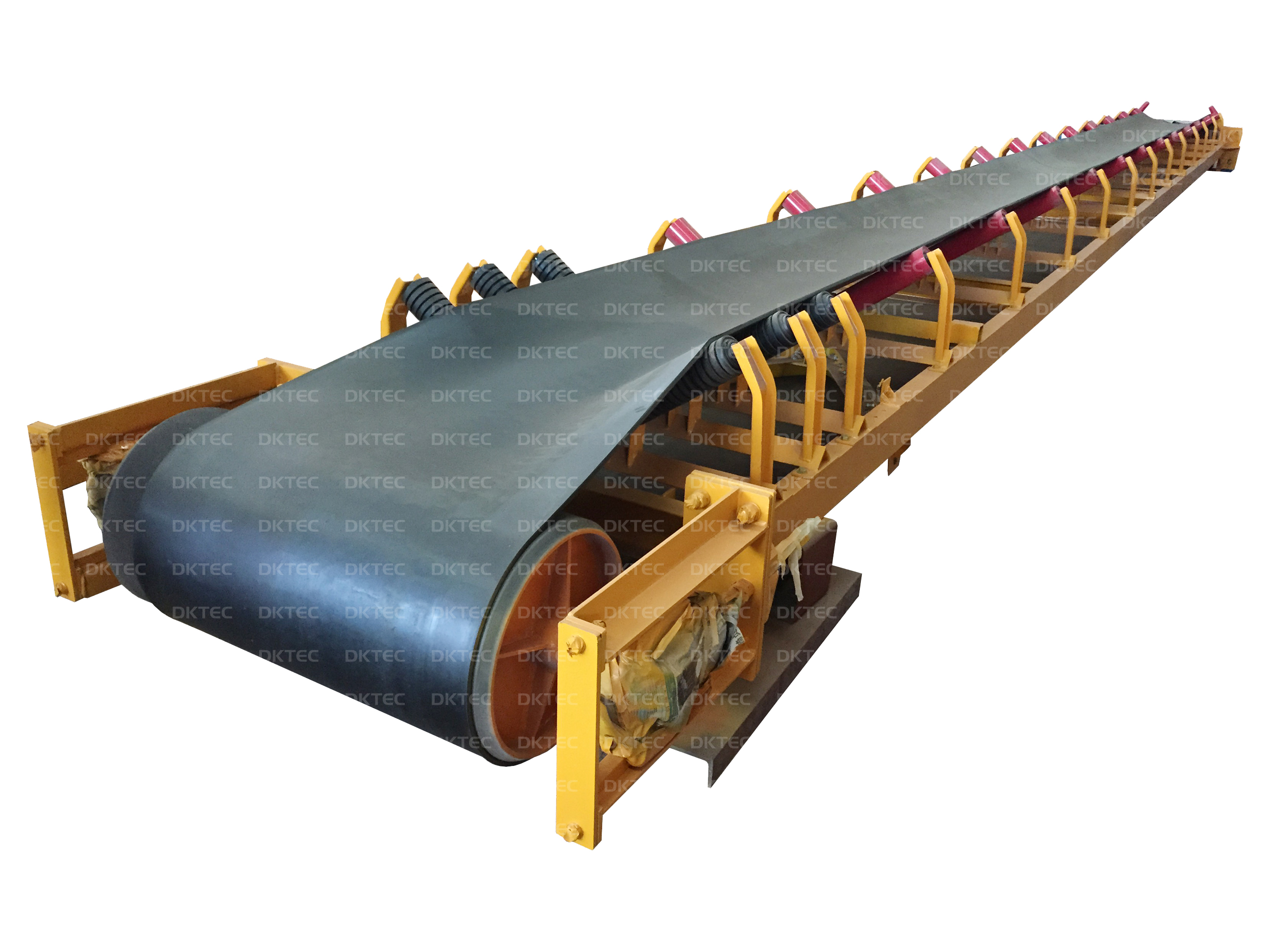

Flat belt conveyor

| Belt width(mm) | power | speed | capacity |

| B650 | 11-15kw | 1.6-2.0m/s | 200-400t/h |

| B800 | 11-15kw | 1.6-2.0m/s | 300-500t/h |

| B1000 | 15-18.5kw | 1.6-2.0m/s | 400-600t/h |

| B1200 | 15-22kw | 1.6-2.0m/s | 500-700t/h |

Inclined belt conveyor-herringbone belt

| Belt width(mm) | power | speed | capacity |

| B650 | 11-18.5kw | 2.0-2.5m/s | 150-250t/h |

| B800 | 15-22kw | 2.0-2.5m/s | 200-300t/h |

| B1000 | 30-45kw | 2.0-2.5m/s | 300-450t/h |

| B1200 | 37-55kw | 2.0-2.5m/s | 400-600t/h |

Working characteristics of TD belt conveyor:

DTⅡ, TD75 belt conveyors have two fixed and mobile types according to their support structure: according to the conveyor belt material, there are rubber belts, plastic belts and steel core belts. The working environment temperature of the belt conveyor is generally between -10℃--+40℃, and the material temperature should not exceed 70oC; the heat-resistant rubber belt can transport high-temperature materials below 120oC. When the material temperature is higher, the belt conveyor is not suitable. When transporting materials with acid and alkaline oils and organic solvents, oil-resistant, acid- and alkali-resistant rubber belt plastic belts are required. The bandwidth of belt conveyors can be divided into: 650, 800, 1000, 1200 . The user can calculate the layout of the conveyor and the selected belt width, canvas layer and thickness of the belt according to the conveying length of the belt conveyor, the type of material, the bulk density, the conveying volume, the conveying length and other factors.

In industrial production, the correct use of conveyor belts is especially important. In industrial production, conveyor belts are accompanied by the expansion of conveyor belts in industrial production. Manufacturers pay attention to multiple varieties, high efficiency, light weight, multi-function, and long life. Several aspects. Pay attention to the following items in use:

1. Avoid the roller being covered by the material, causing the rotation failure, prevent the leakage of the material from being stuck between the roller and the belt, pay attention to the lubrication of the movable part of the conveyor belt, but do not oil the conveyor belt;

2. Prevent the conveyor belt load from starting;

3. If the conveyor belt deviates, measures should be taken to correct it in time;

4. When the conveyor belt is found to be partially damaged, use artificial cotton to repair it in time to avoid expansion;

5. Avoid the conveyor belt from observing the block of the frame, pillar or block material to prevent it from breaking and tearing