SICOMA CONCRETE MIXER

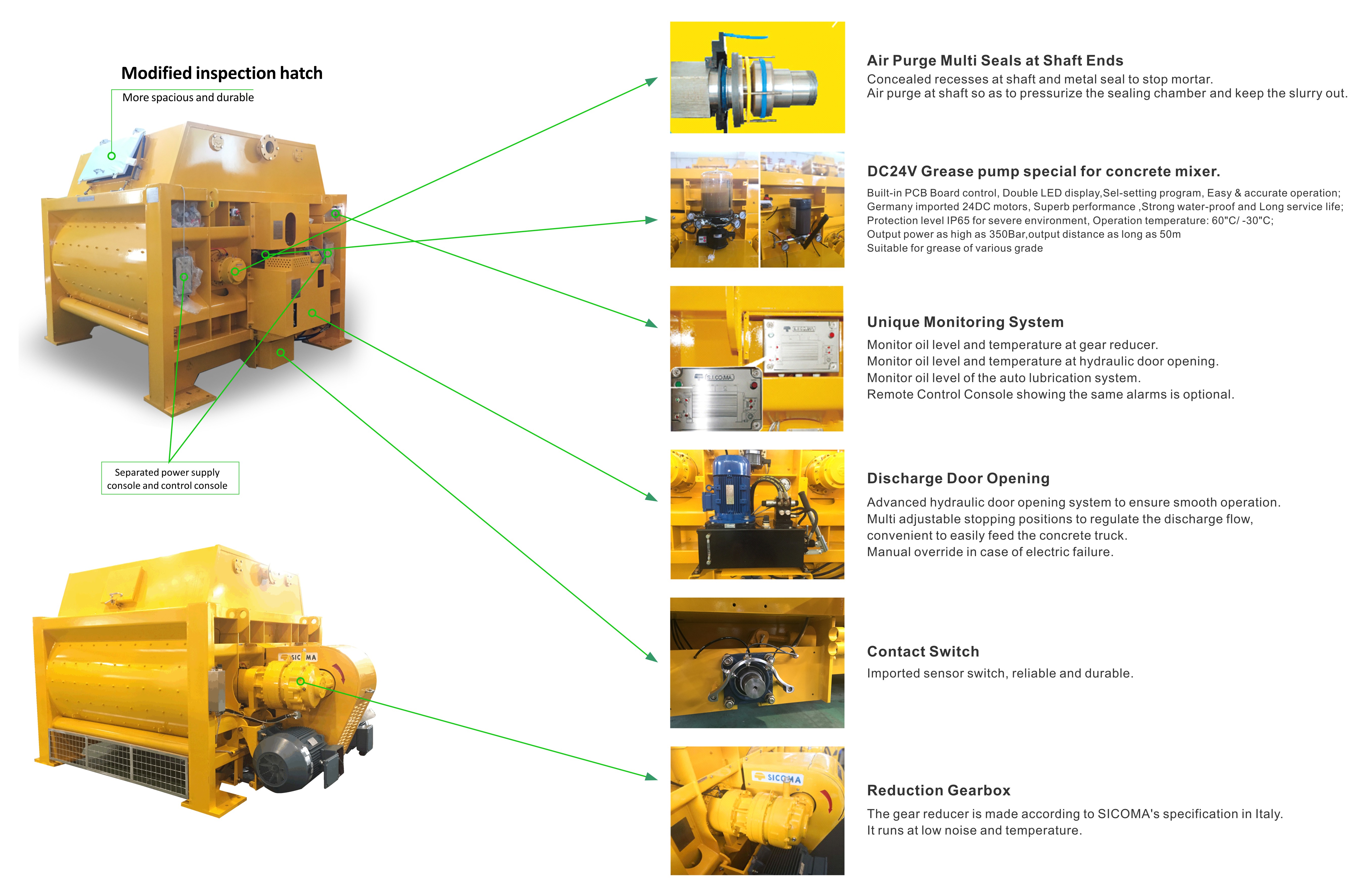

SICOMA produces a series of mixers of multiple models. According to customer needs, our company chooses most of the standard MAO/MSO/MEO/MPC/AMP mainframes. The machine is mainly composed of seven system parts: Mixing tank / Mixing system / Junction box / Monitoring and alarm system / Lubrication-sealing system (not for MPC/AMP series) / Discharging system / Transmission system

MAO3000/2000 MAO4500/3000

- Shatt ends multi soal protection and air purge soal protection to oflielly prevent loakage.

- Uniquo mixer monitoring system to monitor working condilions of goarbox,discharge door pump. and electronic lubric ation pump.

- With DC 24V grease pump system special tor concrete mixer, sell. programmed running time.wator- proof. dust-proof, superb performanco.

- Multl-pipe water spraying system to ensure oven water distribution.

- Heavy duty design, stablo operation.

- Reinforced gearbox processed with military materials by high- precision technology. high loadcapacity and longer servico lile.

- Capacity rangod lrom 15 cu. m to 6.0cu m.

- Optional itering coling oystem, grease-free and watercooling shat end sealig system, camera systemhigh pressure washing system, weighing system and microw ave moisture monitoring system.

| Model | MAO3000/2000 | MAO45O0/3000 | MAO6000/4000 |

| Dry filling capactity(L) | 3000 | 4500 | 6000 |

| Compacted yield(L) | 2000 | 3000 | 4000 |

| Mixing speed(r/m) | 24.5 | 24.5 | 24.5 |

| Mixing cycle(s) | 30 | 30 | 30 |

| Mixing blades (prece) | 14 | 16 | 20 |

| Mixing motor & power(kw) | 2×37 | 2×55 | 2×75 |

| Weight at empty(KG) | 7500 | 9200 | 11800 |

MSO1500/1000 MSO2250/1500

- Equipped With Multi Shaft Seals

- Equipped With Manual Lubrication Pump

- Watering Curtain At Top Cover To Ensure Fast And Thorough Mixing

- Automatic Lubrication Pump DC24v

- Capacity Ranged From0.5cu.m To 1.5cu.m

| Model | MSO750/500 | MSO1500/1000 | MSO2250/1500 |

| Dry filling capacity(L) | 750 | 1500 | 2250 |

| Compacted yield(L) | 500 | 1000 | 1500 |

| Mixing speed(r/m) | 29 | 27 | 27 |

| Mixing cycle(s) | 30 | 30 | 30 |

| Mixing blades(pcs) | 14 | 12 | 14 |

| Mixing motor&power(kw) | 2×11 | 2×22 | 2X30 |

| Weight at empty(KG) | 3600 | 5000 | 5600 |

MEO1500/1000 MEO3000/2000

- Equipped with multi stages shaft seals,

- Equipped with manual lubrication pump.

- Optional automatic lubrication pumpDC24V.

- High resistance to overload, low-noise,stable operation.Easy maintenance, spare parts at reasonable price, highratio between the performance and the price.

- Capacity ranged from 2.0 cu.m.

- Fit for batching plant, fly- ash solidification and otherenvironmental-friendly mixing projects.

| Model | MEO1250/750 | MEO1500/1000 |

| Dry filling capacity(L) | 1250 | 1500 |

| Compacted yield(L) | 750 | 1000 |

| Mixing speed(r/m) | 27 | 27 |

| Mixing cycle(s) | 30 | 30 |

| Mixing blades(pcs) | 10 | 10 |

| Mixing motor&power(kw) | 2×18.5 | 2×22 |

| Weight at empty(KG) | 4300 | 4500 |

MPC1500/1000 MPC2250/1500

- Planetary mixing mode is suitable for mixing high-purity concrete, which can make the mixing of materials more uniform;

- It is an ideal choice for the block and precast parts industry;

- The discharge door can be opened and closed by hydraulic/manual dual method, which can be used for multiple stops;

- The discharge port can choose three other directions, and it can open more than two at the same time;

- Economical and durable, easy to maintain;

- Compared with the twin-shaft mixer with the same volume, the height is low, and the layout planning of the mixing station is easy;

- Optional aggregate lifting device;

- The company has long-term supply of wearing parts;

- Available in 0.25m3~3.0m3 and other specifications.

| Model |

MPC750/500 |

MPC1500/1000 |

MPC2250/1500 |

| Capacity(L) |

500 |

1000 |

1500 |

| Motor power(kw) |

22 |

45 |

2×37 |

| Planetary speed(r/m) |

21 |

21 |

15 |

| Spider speed(r/m) |

44 |

44 |

30+30 |

| Number of long mixing arm(pc) |

1 |

1 |

1 |

| Number of short mixing arm(pc) |

1 |

1 |

1 |

| Number of mixing arm(pc) |

3 |

3 |

3+3 |

| Weight(KG) |

2400 |

4000 |

6300 |

Air Purge Multi Seals At Shaft Ends

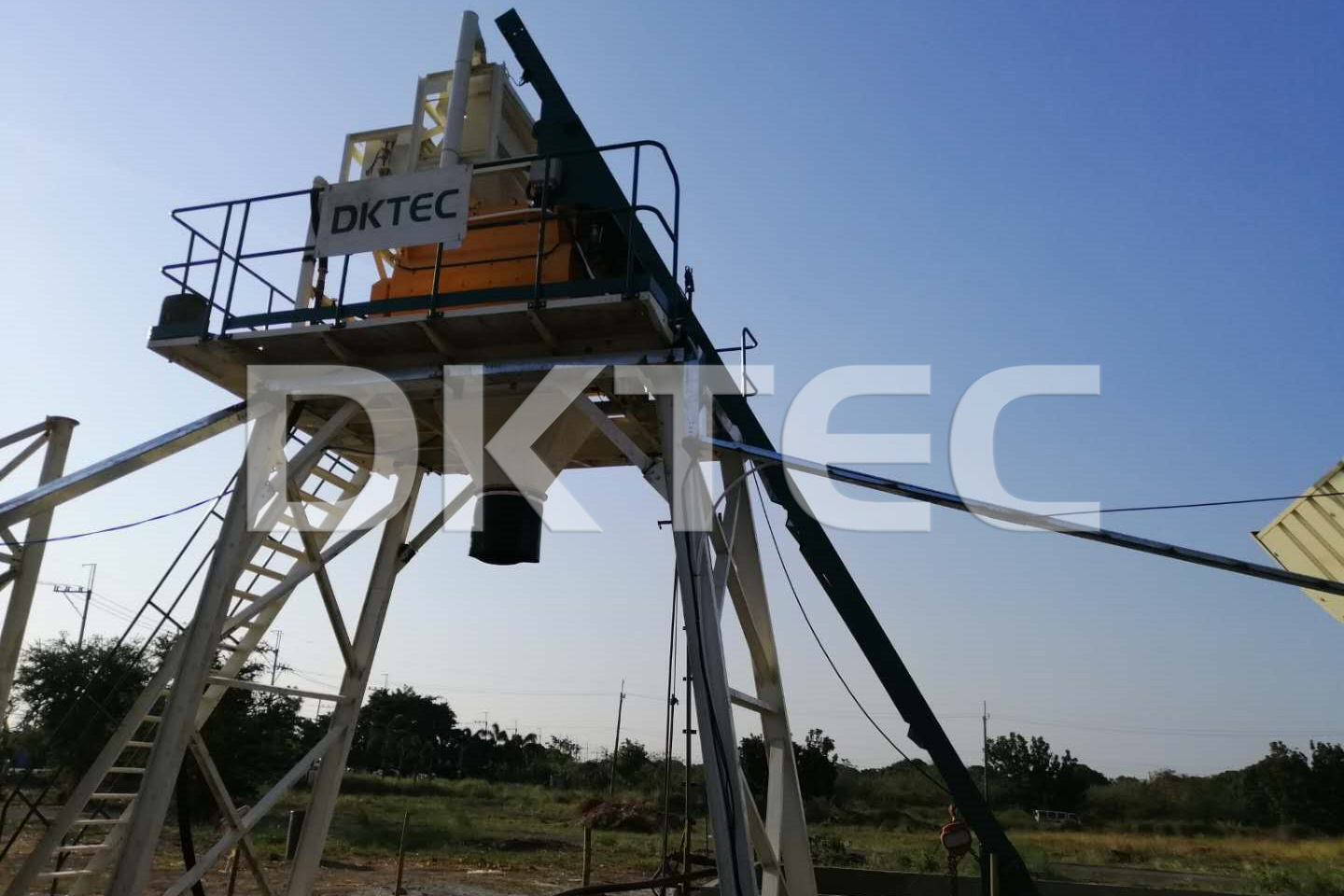

Project Cases

Delivery Photo

Maintenance Of Concrete Mixer

- Ensure the cleanliness of the machine and surrounding environment.

- Clear the accumulated material in the hopper in time to make the sensor return to zero normally.

- Check whether the lubricating oil at each lubrication point is sufficient, and the lubricator in the air system should maintain sufficient oil.

- Check whether the motors and electrical appliances are overheated, abnormal noise, whether the indicator is normal, and the signal system is intact.

- Check and adjust the cylinder, butterfly valve and solenoid valve frequently to make the opening and closing meet the requirements.

- Check all systems frequently, and deal with it in time if there is dust leakage, gas leakage, oil leakage and electricity leakage.

- The mixer and discharge hopper should be cleaned every four hours to prevent the residual concrete from solidifying and hindering normal operation.

- Every shift should release the internal water of the air compressor, air storage tank and filter, and eliminate the malfunctions that occur during operation.

- The butterfly valve, mixer, solenoid valve, air filter and oil mist device are maintained in accordance with the relevant instructions.