Consistently high mixture homogeneity and short mixing cycles

● Rapid increase in mixture homogeneity through intensive material exchange

● Uniform consistency and homogeneity in every mixing cycle

Optimum energy efficiency

● Excellent mixing performance despite low mixer speed

● Preservation of the grain structure of the formulation’s individual components

● Low specific energy consumption due to short mixing times, optimized mixing mechanism and efficient drive

Design results in low wear

● Low wear on mixing tools and mixing trough lining due to low speeds and compact design

● Significantly less wear and tear than with pan or planetary mixers

● Optimized design of all parts subject to wear

Efficient production of concrete

● Excellent liberation of binders in a short time

● Creates potential for reducing the required amount of binder

● Uniform and fast distribution of additives and admixtures across the entire volume of the mixture

● Possibility of small batches as low as 10% of the nominal filling level

● Safe investment in view of modern concrete formulations

● Supports hybrid mixing cycles (slow – fast – slow)

| Type | Dry charge,

aggregates and binder |

Compacted

concrete per batch |

Compacted concrete output | Drive system

(ready-mixed concrete) 3) |

Maximum aggregate sizes | ||||

| with truck mixer

discharge 1) |

with open truck

discharge 2) |

Ready-mixed

concrete |

Hydrodam

concrete 4) |

||||||

| DKX 1.00 | 2 yd³ 1.5 m³ |

1.3 yd³ 1 m³ | 58 cycles/h | 76 yd³/h 58 m³/h |

60 cycles/h | 78 yd³/h 60 m³/h |

50 hp 37 kW |

2½ in 64 mm | 3 in 80 mm |

| DKX 1.25 | 2.5 yd³ 1.88 m³ |

1.6 yd³ 1.25 m³ |

53 cycles/h | 86 yd³/h 66 m³/h |

53 cycles/h | 86 yd³/h 66 m³/h |

60 hp 45 kW |

2½ in 64 mm | 5 in 125 mm |

| DKX 2.25 | 4.5 yd³ 3.38 m³ |

3 yd³ 2.25 m³ |

46 cycles/h | 136 yd³/h 104 m³/h |

50 cycles/h | 148 yd³/h 113 m³/h |

100 hp 75 kW |

2½ in 64 mm | 6 in 150 mm |

| DKX 3.00 | 6 yd³ 4.5 m³ |

4 yd³ 3 m³ |

44 cycles/h | 173 yd³/h 132 m³/h |

53 cycles/h | 208 yd³/h 159 m³/h |

2 x 75 hp 2 x 55 kW |

2½ in 64 mm | 6 in 150 mm |

| DKX 4.00 | 7.9 yd³ 6 m³ | 5.2 yd³ 4 m³ | 39 cycles/h | 204 yd³/h 156 m³/h |

49 cycles/h | 256 yd³/h 196 m³/h |

2 x 100 hp 2 x 75 kW |

2½ in 64 mm | 6¼ in 160 mm |

| DKX 4.50 | 9 yd³ 6.75 m³ |

6 yd³ 4.5 m³ |

37 cycles/h | 218 yd³/h 167 m³/h |

51 cycles/h | 301 yd³/h 230 m³/h |

2 x 100 hp 2 x 75 kW |

2½ in 64 mm | 6¼ in 160 mm |

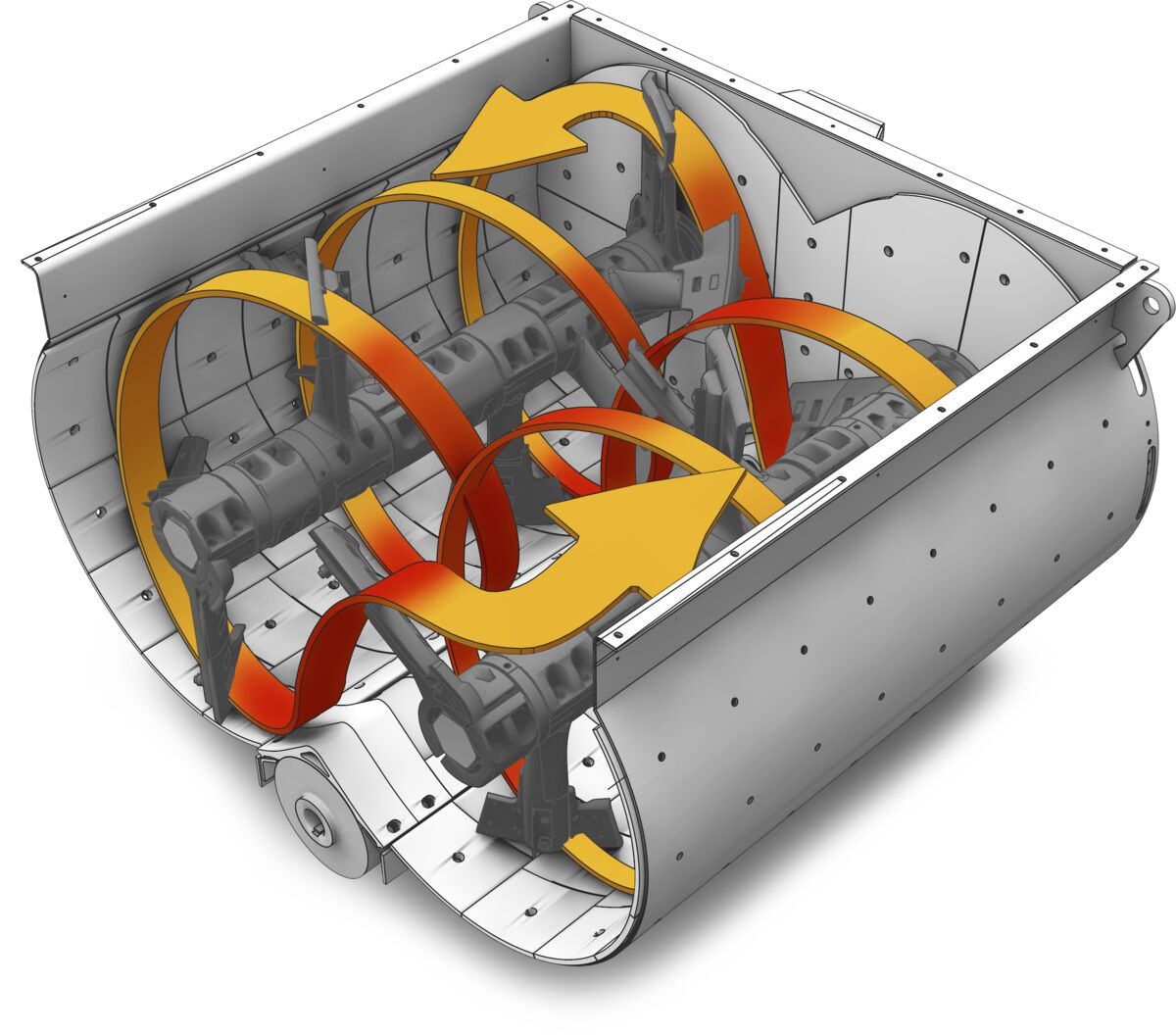

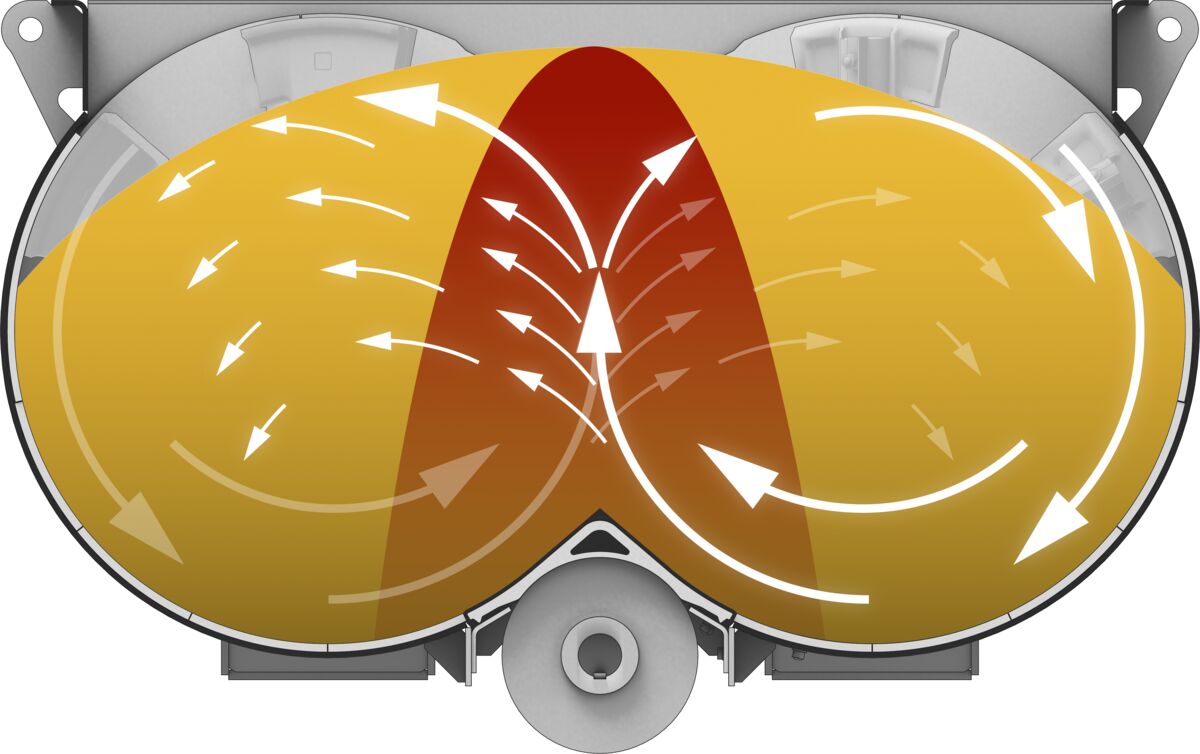

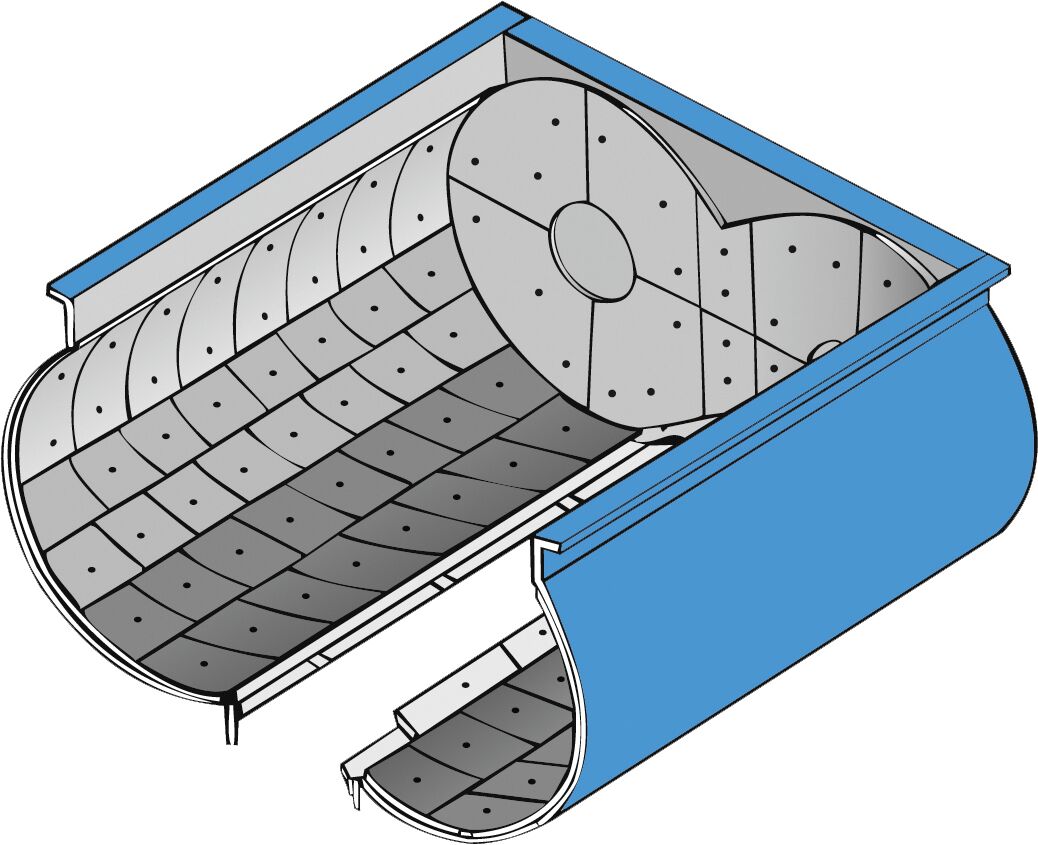

In contrast to the circular motion of other mixing systems, the three-dimensional mixing principle of the twin-shaft batch mixer produces a more intensive exchange of material, which leads to shorter mixing times while consuming less energy.

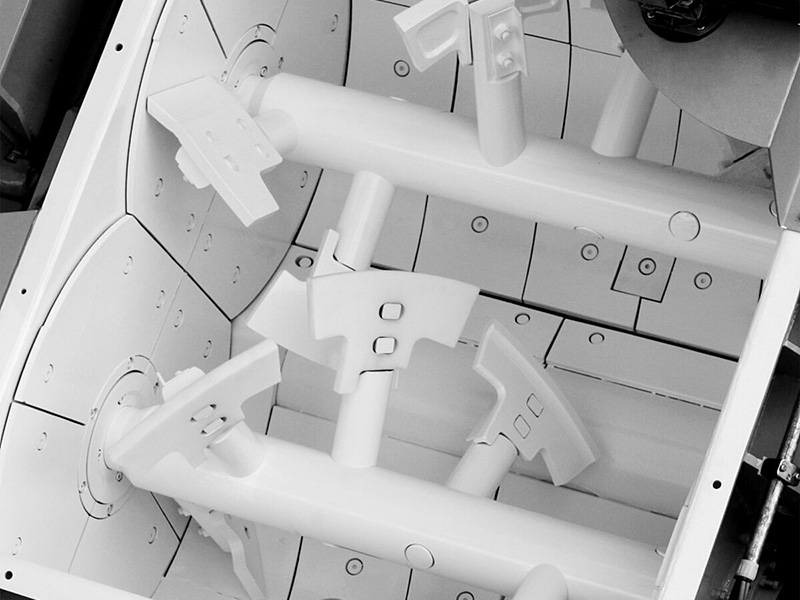

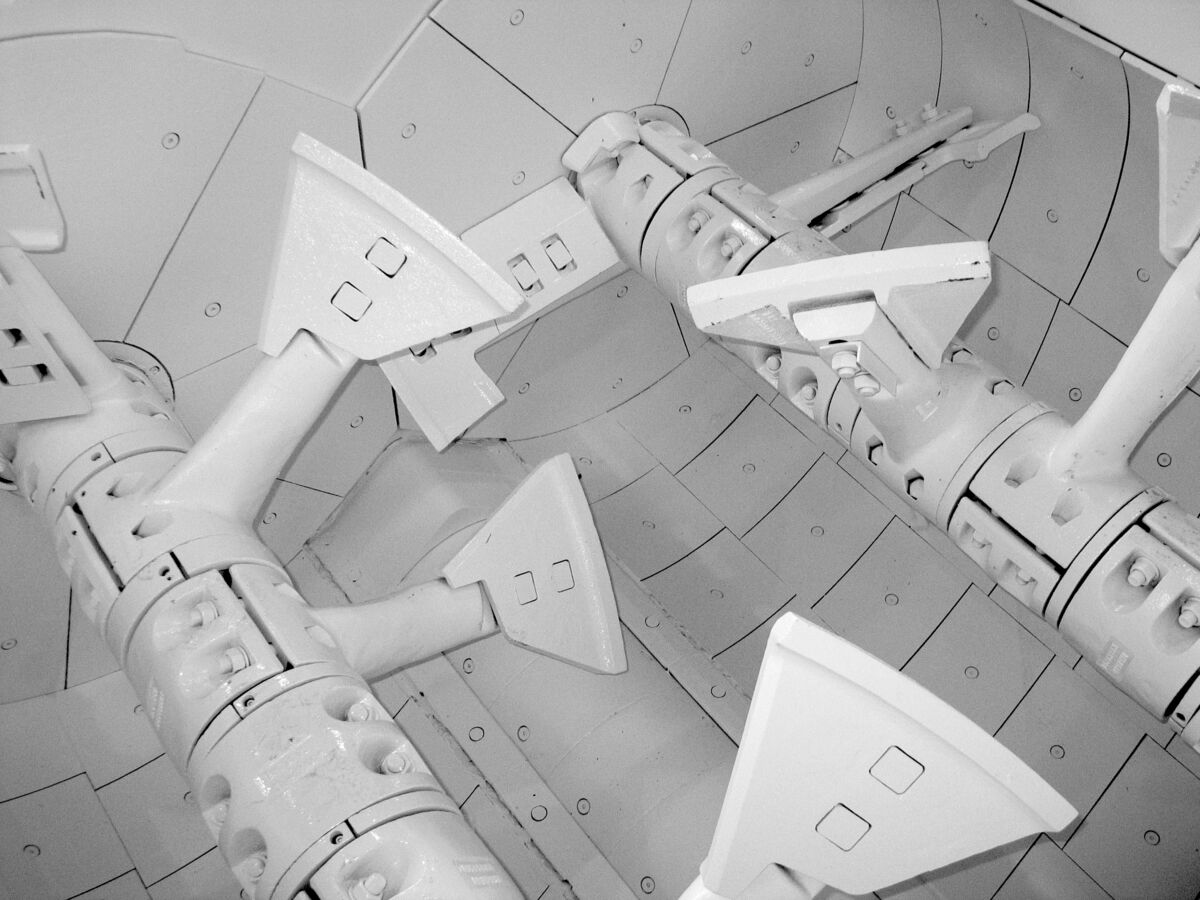

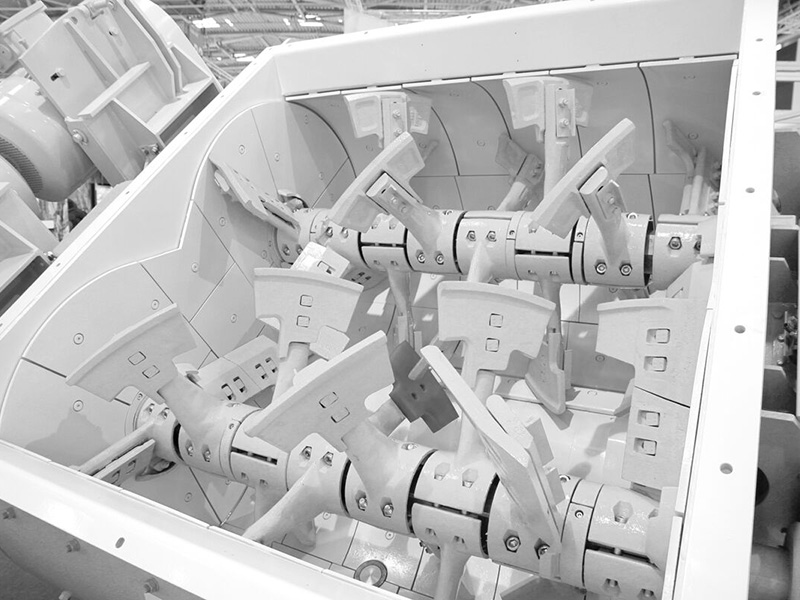

Spiral mixing tools

● Mixing tools arranged on each mixing shaft in the shape of an interrupted spiral

● Two counter-rotating mixing shafts with the mixing tools overlapping in the longitudinal center of the mixer

● Counter blades positioned at the ends of the shafts

● Moderate circumferential speed of the mixing blades for gentle processing

● High-quality hexagonal shaft with high torsional and bending strength

● Streamlined mixing arms made of special cast steel

● Helical arrangement of the mixing arms as spiral mixer

● Easily adjustable mixer blades

Mixing principle

● Generation of a circular three-dimensional movement pattern of the entire mixture

● Intensive material exchange in the turbulent overlap zone of the two mixing circuits

● Optimal conversion of the energy input into intensive relative movements of the mixture

● Total volume of material is always included in the mixing process

Mixing mechanisms

Universal mixing unit

This features a 60° arm inclination for the production of ready-mixed concrete, precast concrete, special concretes and many other mixing materials.

Smooth mixing tools

This serves to reduce adhesions to a minimum, even when processing sticky mixtures.

Coarse particle mixing system

For the production of concrete used in dam construction, this system is suitable for aggregates up to 180 mm, depending on mixer size.

Twin mixing mechanism

For the production of dry and moist mixtures with many fine particles. This doubling of the mixing arms significantly increases the number of relative movements in the mixture, resulting in shorter mixing cycles

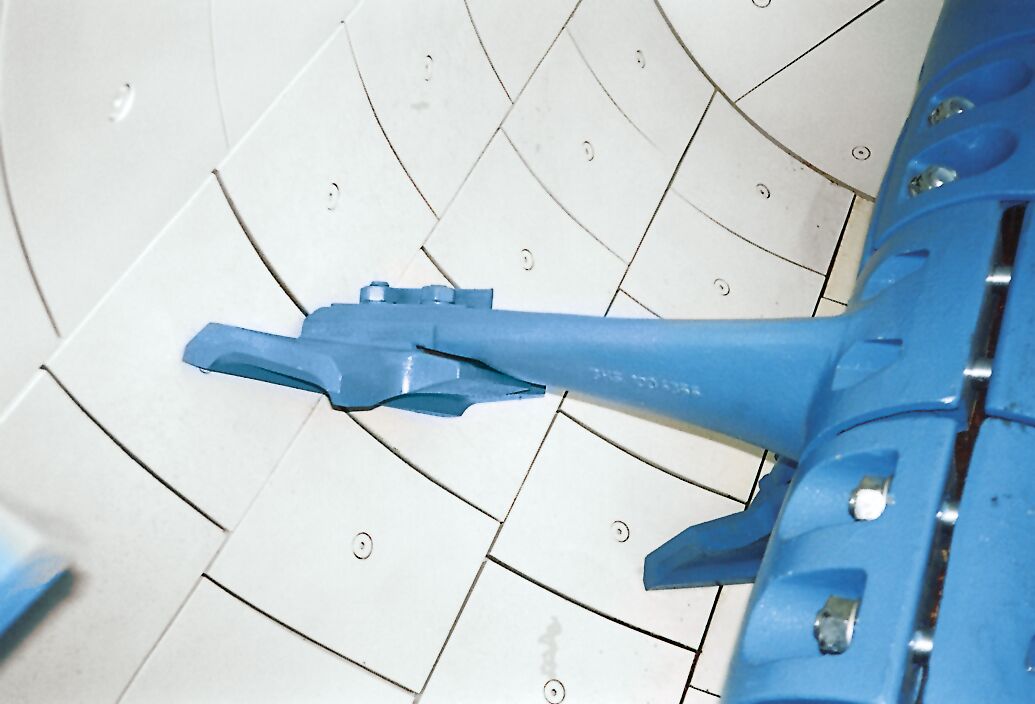

Wear lining

Diamond-shaped tiles

Diamond-shaped tiles with a material thickness of 19 mm made from optimized chrome chilled cast alloy can be used as mixing trough lining. The service life improves by up to 30 % compared to rectangular tiles.

OPTILONG tiles

We offer rhombus-shaped tiles with a material thickness of 28 mm for high-wear applications. The variable hardness of the individual tile rows ensures uniform abrasion across all wear zones. This nearly doubles the service life compared to the 19-mm rhombic tiles.

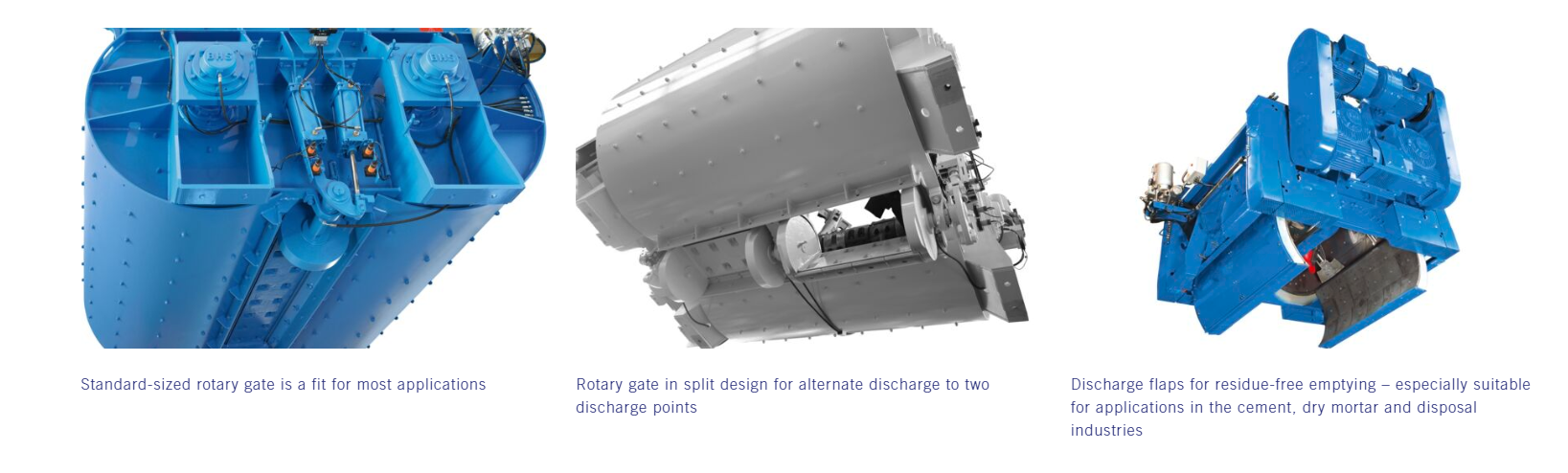

Discharge gate design features

● Solid and robust cast construction

● Centrally located between the two mixing shafts

● Effective sealing due to adjustable gate rails

● Precise regulation of the discharge volume

● Reliable actuation using pneumatic or hydraulic cylinders

Wear lining

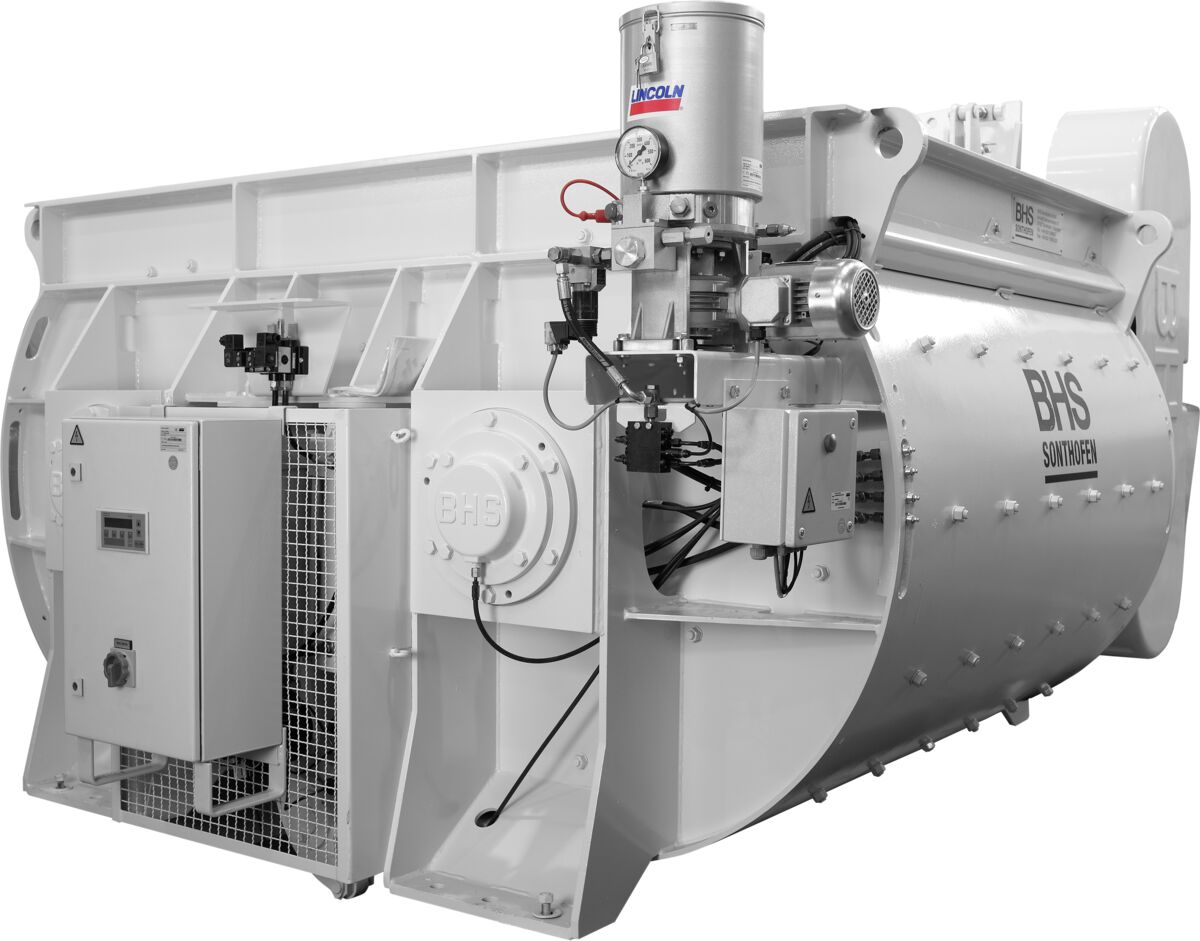

Impulse-driven central lubrication

The impulse-driven central lubrication system supplies the internal axial face seals with grease. After mixer cleaning or when required, lubrication of the seals can be triggered via the control unit at the push of a button. The running time is freely adjustable.

Fully automatic central lubrication

The lubrication points of the four axial face seals, the four internal mixer trough seals (and, as an option, the other lubrication points of the mixer) are automatically supplied with grease via a PLC controller and by means of a progressive distributor. To lubricate the system after mixer cleaning, it is sufficient to trigger the grease pump via the PLC control.