Cement silos, also called cement tanks, can also be divided into split cement silo and integral welded cement silo. Split silo is generally suitable for container transportation to save transportation cost and cycle. Cement is used together with the supporting concrete mixing plant, and the user replaces cement silos with different capacities and quantities according to the output of the mixing plant. It is one of the main parts of the concrete mixing plant. In addition to storing cement, it can also store bulk materials, such as fly ash, fine ore, dry mortar, grain, etc. The silo has only rainproof, moisture-proof and easy-to-use features. It can be used with butterfly valves, screw conveyors, flexible connection sleeves, etc., to transport materials from the silo to the metering bucket. The silo generally contains a dust collector and a pressure release valve. , High and low level level gauge, flow aid air bowl, discharge gate butterfly valve, filter device and control cabinet. Sealed transportation to ensure a dust-free working environment.

|

Specification |

||||

| Model No. | Capacity | Silo diameter | Silo height | Discharge height |

| DKS50T | 50T | 3.16m | 12.9m | 4.5m |

| DKS80T | 80T | 3.16m | 15.70m | 4.5m |

| DKS100T | 100T | 3.16m | 17.2m | 4.5m |

| DKS150T | 150T | 3.16m | 21.4m | 4.5m |

| DKS200T | 200T | 4.5m | 17.8m | 4.5m |

| DKS300T | 300T | 5.3m | 18.9m | 4.5m |

| DKS500T | 300T | 6.8m | 18.3m | 2.5m |

|

Selection Suggestions |

||

| Silo model | Plant capacity | Qty per plant |

| DKS50T/100T | 60m³/h | 1/2 |

| DKS100T | 90m³/h | 2/3 |

| DKS100T/120T | 120m³/h | 1/4 |

| DKS200T/300T | 180m³/h | 3/4 |

| DKS300T | 240m³/h | 3/4 |

Cement silo is mainly made of Q235 steel plant to store the cement. It have two types,bolted silo & welded silo,the capacity of silo is from 30t-1000t.

The cement silo includes the following parts: outriggers, maintenance platform, tank body, ladder, guardrail, feed pipe, silo roof dust collector, pressure release valve, high and low level gauge, flow aid gas bowl, discharge gate butterfly valve, filter device And control cabinet

Main Feature:

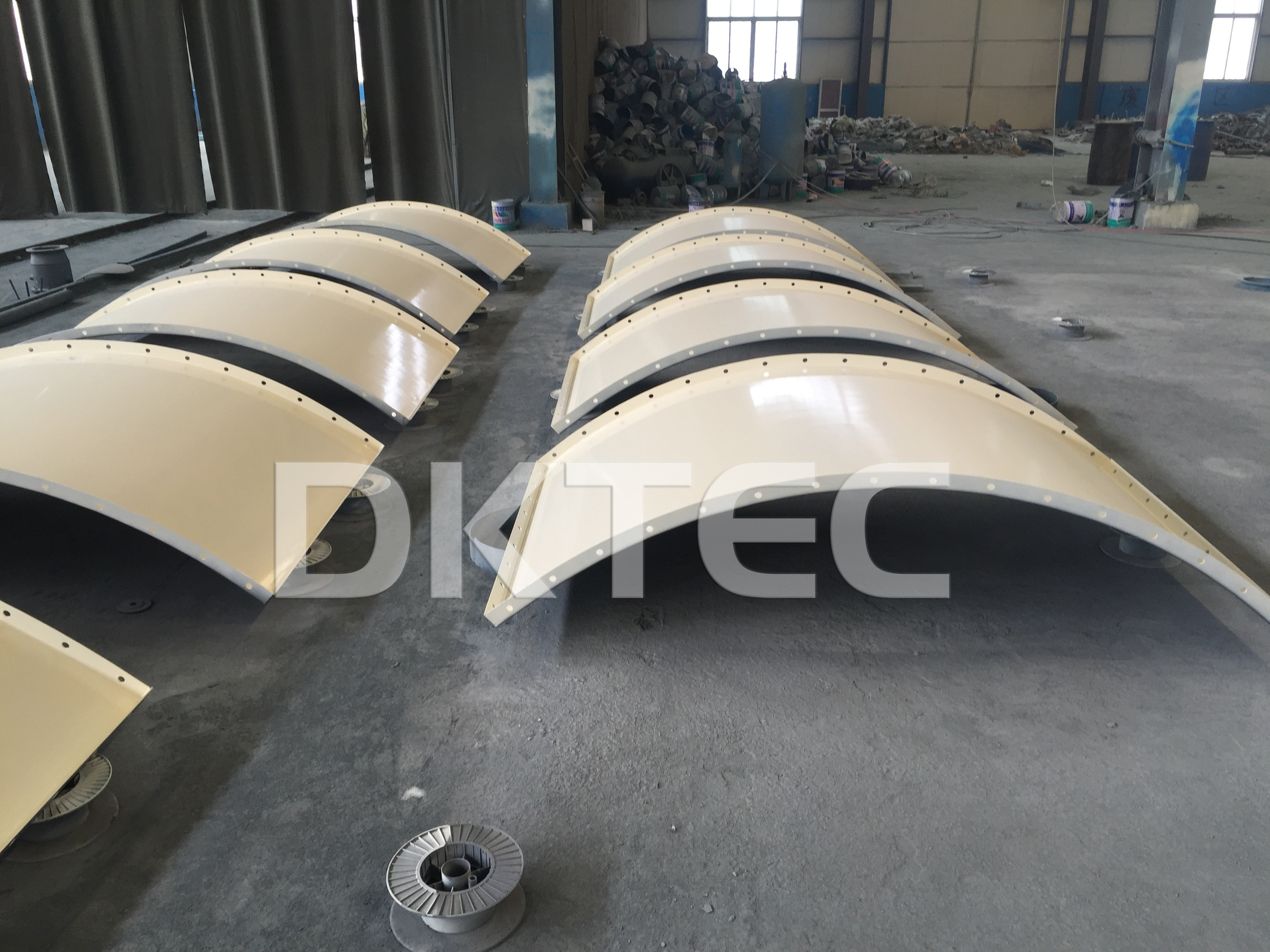

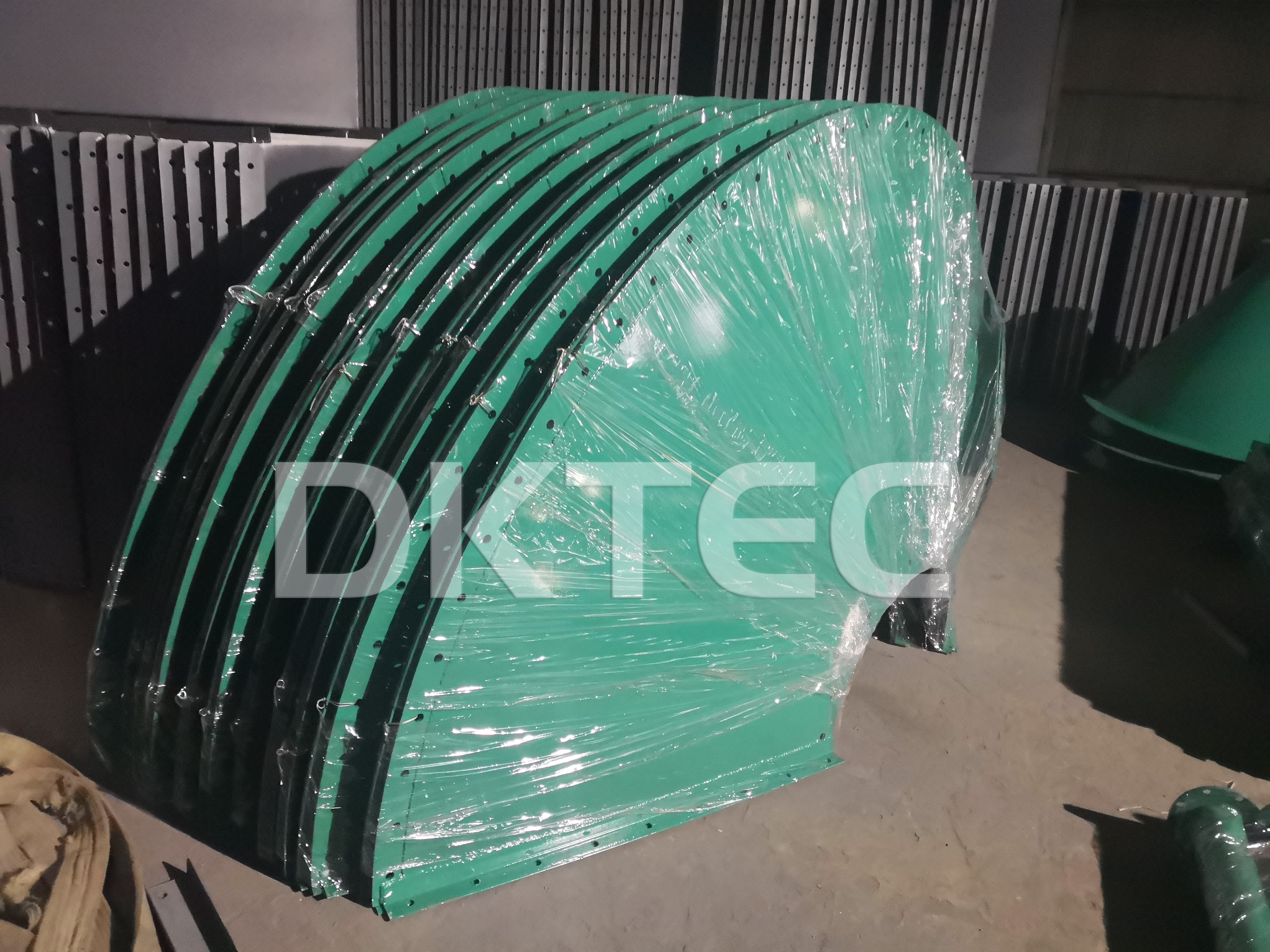

1. The flaky cement silo is easy to install and dismantle.

2. It can be packed and transported easily.

3. Strong sealing performance.

4. Beautiful appearance.

Installation: The cement silo consists of steel plates, which are connected by bolts, which is very easy to assemble and disassemble. Experienced workers can complete the installation of the cement silo through installation videos or installation instructions.

Capacity: The bolt cement silo can be used for 50 tons, 100 tons, 200 tons, 300 tons, 500 tons, 1000 tons. The final size is designed according to the local environment and local requirements, so each cement silo solution is unique to the customer.

if you have any questions,pls contact us:sales@dongkunchina.com

Performance characteristics

1. Cement tanks are usually used as supporting products for concrete mixing plants (buildings).

2. It is suitable for loading bulk cement and dry fly ash. It has the characteristics of rainproof, moisture-proof and easy to use; specifications and dimensions can also be made according to customer requirements.

3. Generally it is a cylindrical support structure, with dust removal equipment on the upper part to prevent dust leakage, and an arch breaking device at the lower part to prevent the powder from agglomeration and make the powder unload smoothly. It is also equipped with material level sensing equipment, which can be controlled at any time. Material usage.

4. Generally, a bulk cement conveyor truck is used to send the powder gas into the silo; according to the structure of the cement silo, there are generally two ways to unload the material, one is to connect the lower part to the screw conveyor, and use the screw conveyor to send the powder into the powder. The second is to use pneumatic conveying (for cement tanks with special structures).

5. The cement silo has simple structure, convenient installation, small floor space, low investment, strong mobility, etc.

6. The bolt cement silo can be used for 50 tons, 100 tons, 200 tons, 300 tons, 500 tons, 1000 tons. The final size is designed according to the local environment and local requirements,