Flat Belt

The multi texitle convey belt is widely applied to conveying material in the field of mine, ports, metallurgy. There are plenty kinds of fiber type such as polyester, cotton, terylene, polyamide, monofilament, and we mainly use nylon( polyamide), polyester EP type belt. Please following specification

|

Textile Item |

Structure |

Textile Item |

Thickness |

Tensile Strength(N/M) |

Thickness of cover rubber (mm) |

Wide Range (mm) |

|||||

|

Warp |

Weft |

2Ply |

3ply |

4ply |

5ply |

6ply |

|||||

|

NN |

Nylon |

Nylon |

Nn100 |

1 |

200 |

300 |

400 |

500 |

600 |

300-2500 |

≤300 |

|

Nn125 |

1 |

250 |

375 |

500 |

625 |

750 |

300-2500 |

≤300 |

|||

|

Nn150 |

1.1 |

300 |

450 |

600 |

750 |

900 |

300-2500 |

≤300 |

|||

|

Nn200 |

1.2 |

400 |

600 |

800 |

1000 |

1200 |

300-2500 |

≤300 |

|||

|

Nn250 |

1.4 |

500 |

750 |

1000 |

1250 |

1500 |

300-2500 |

≤300 |

|||

|

Nn300 |

1.6 |

600 |

900 |

1200 |

1500 |

1800 |

300-2500 |

≤300 |

|||

|

Nn350 |

1.8 |

700 |

1050 |

1400 |

1750 |

2100 |

300-2500 |

≤300 |

|||

|

Nn400 |

1.9 |

800 |

1200 |

1600 |

2000 |

2400 |

300-2500 |

≤300 |

|||

|

Nn500 |

2.1 |

1000 |

1500 |

2000 |

2500 |

3000 |

300-2500 |

≤300 |

|||

|

Nn630 |

2.4 |

1260 |

1890 |

2520 |

3150 |

3780 |

300-2500 |

≤300 |

|||

|

Textile Item |

Structure |

Textile Item |

Thickness |

Tensile Strength(N/M) |

Thickness of cover rubber (mm) |

Wide Range (mm) |

|||||

|

Warp |

Weft |

2Ply |

3ply |

4ply |

5ply |

6ply |

|||||

|

EP |

Polyester |

Nylon |

Nn100 |

1 |

200 |

300 |

400 |

500 |

600 |

300-2500 |

≤300 |

|

Nn125 |

1 |

250 |

375 |

500 |

625 |

750 |

300-2500 |

≤300 |

|||

|

Nn150 |

1.1 |

300 |

450 |

600 |

750 |

900 |

300-2500 |

≤300 |

|||

|

Nn200 |

1.2 |

400 |

600 |

800 |

1000 |

1200 |

300-2500 |

≤300 |

|||

|

Nn250 |

1.4 |

500 |

750 |

1000 |

1250 |

1500 |

300-2500 |

≤300 |

|||

|

Nn300 |

1.6 |

600 |

900 |

1200 |

1500 |

1800 |

300-2500 |

≤300 |

|||

|

Nn350 |

1.8 |

700 |

1050 |

1400 |

1750 |

2100 |

300-2500 |

≤300 |

|||

|

Nn400 |

1.9 |

800 |

1200 |

1600 |

2000 |

2400 |

300-2500 |

≤300 |

|||

|

Nn500 |

2.1 |

1000 |

1500 |

2000 |

2500 |

3000 |

300-2500 |

≤300 |

|||

|

Nn630 |

2.4 |

1260 |

1890 |

2520 |

3150 |

3780 |

300-2500 |

≤300 |

|||

Fabric model selection

| Textile Item | Structure | Drum diameter corresponding to the number of fabric layer(mm) | |||||

| 2 | 3 | 4 | 5 | 6 | 7 | ||

| EP | EP200 | 200 | 250 | 315 | 400 | 500 | 630 |

| EP125 | 200 | 250 | 315 | 400 | 630 | 800 | |

| EP150 | 250 | 315 | 400 | 630 | 800 | 1000 | |

| EP200 | 315 | 500 | 630 | 800 | 1000 | 1250 | |

| EP250 | 400 | 630 | 800 | 1000 | 1250 | 1400 | |

| EP300 | 500 | 630 | 800 | 1000 | 1250 | 1400 | |

| NN | NN100 | 200 | 250 | 315 | 400 | 500 | 630 |

| NN125 | 200 | 250 | 315 | 400 | 500 | 630 | |

| NN150 | 200 | 250 | 315 | 400 | 500 | 630 | |

| NN200 | 250 | 315 | 400 | 500 | 630 | 800 | |

| NN250 | 315 | 400 | 500 | 630 | 800 | 1000 | |

| NN300 | 400 | 500 | 630 | 800 | 1000 | 1250 | |

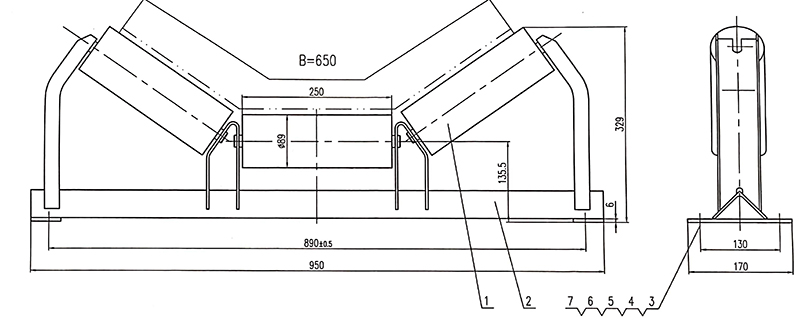

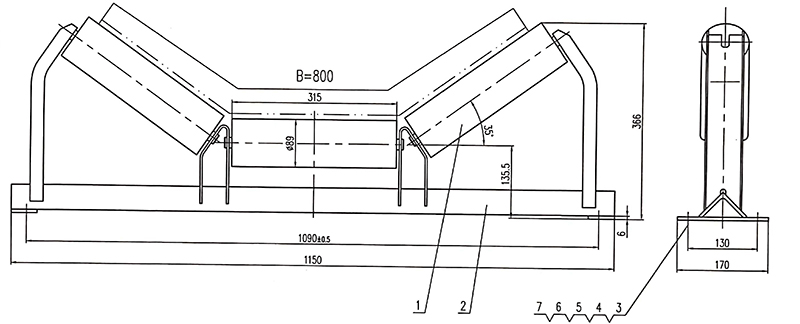

Idler

Bracket idler use hand-held welding, and then painting after surface treatment. That will ensure idler’s precision and strength to make idler long service lift and good appearance. We mainly use TDII trough roller set

B650

B800

B1000

Return to the roller

B650

B800

B1000

Drum

Return to the roller

|

Drum Dia.D (mm) |

Belt Width B(mm) |

Power P (kW) |

Velocity of drum surface V m/s |

|||||||||||

|

0.32 |

0.4 |

0.5 |

0.63 |

0.8 |

1.0 |

1.25 |

1.6 |

2.0 |

2.5 |

3.15 |

4.0 |

|||

|

Φ320 |

400/500/650/800/1000 |

2.2/3.0/4.0 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||

|

5.5/7.5 |

√ |

√ |

√ |

√ |

√ |

√ |

||||||||

|

Φ400 |

400/500/650/800/1000 |

2.2/3.0/4.0 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||

|

5.5/7.5 |

√ |

√ |

√ |

√ |

√ |

√ |

||||||||

|

Φ500 |

500/650/800/1000/1200 |

2.2/3.0/4.0 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||

|

5.5/7.5 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||

|

11/15 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

||||||

|

18.5/22/30/37 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||

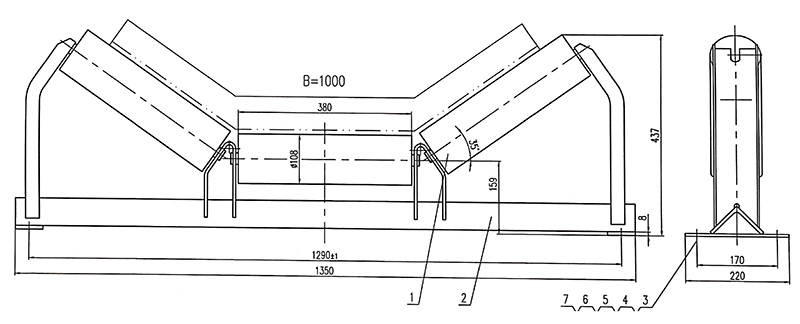

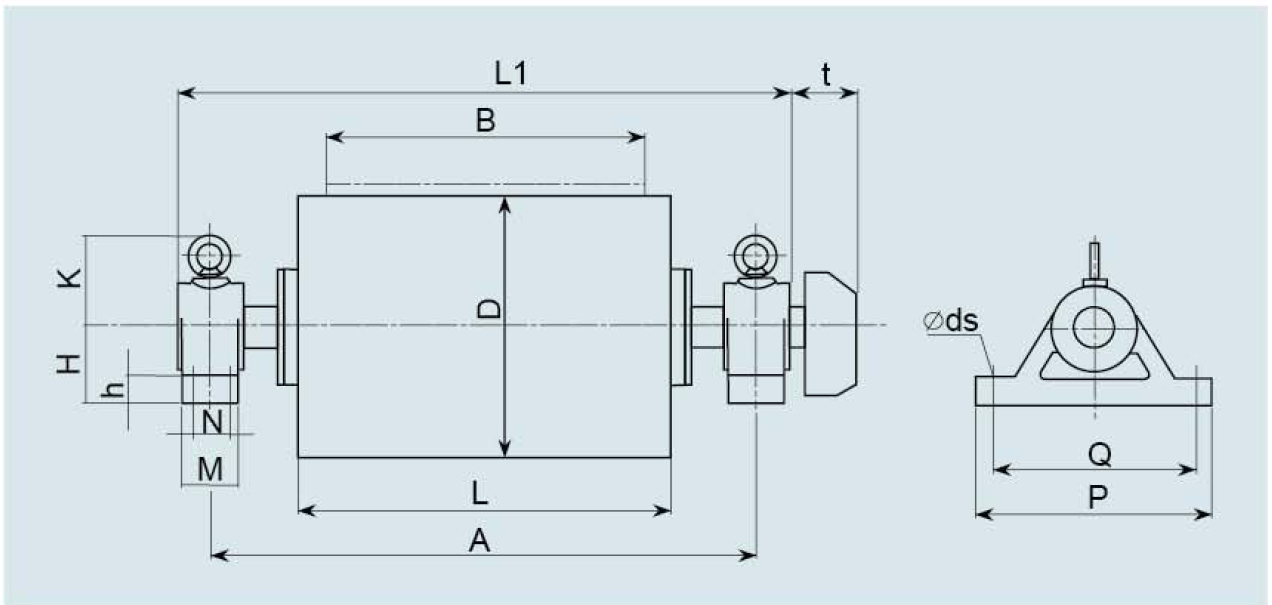

YTH mounting external size

| D | B | A | L | H | C | M | N | P | Q | H | DS |

|

Φ320 Φ400 |

400 | 750 | 500 | 120 | 110 | 90 | - | 340 | 280 | 35 | Φ27 |

| 500 | 850 | 600 | |||||||||

| 650 | 1000 | 750 | |||||||||

| 800 | 1300 | 950 | |||||||||

| 1000 | 1500 | 1150 | |||||||||

| Φ500 | 500 | 850 | 600 | 120 | 120 | 90 | - | 340 | 280 | 35 | Φ27 |

| 650 | 1000 | 750 | |||||||||

| 800 | 1300 | 950 | |||||||||

| 1000 | 1500 | 1150 | |||||||||

| 1200 | 1750 | 1400 | |||||||||

| Φ630

Φ800 Φ1000 Φ1250 |

650 | 1000 | 750 | 120 | 120 | 90 | - | 340 | 280 | 35 | Φ27 |

| 800 | 1300 | 950 | 140 | 140 | 130 | 80 | 400 | 330 | 50 | Φ27 | |

| 1000 | 1500 | 1150 | |||||||||

| 1200 | 1750 | 1400 | 160 | 160 | 150 | 90 | 440 | 360 | 50 | Φ34 | |

| 1400 | 2000 | 1600 | |||||||||

| 1600 | 2200 | 1800 | |||||||||

| 1800 | 2400 | 2000 | |||||||||

| 2000 | 2600 | 2200 |

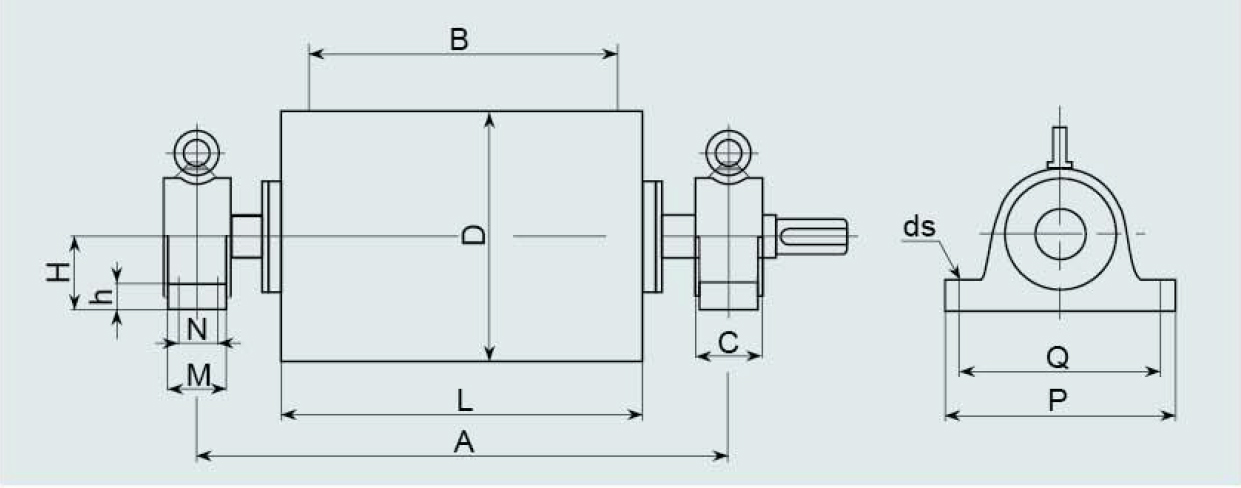

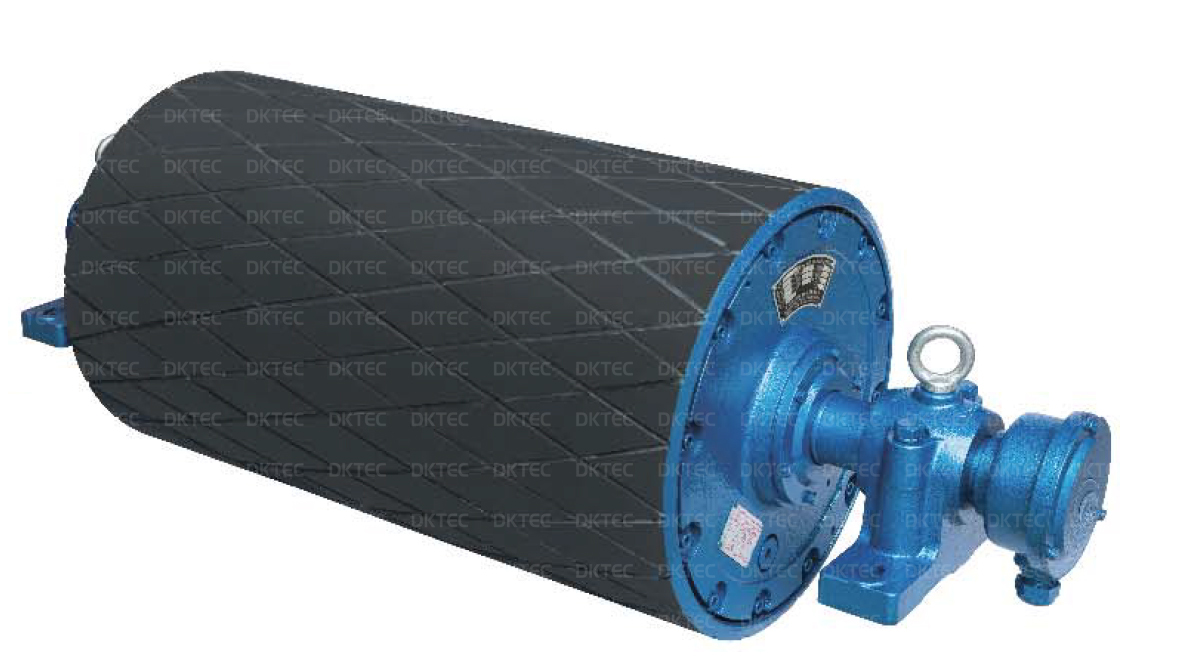

TDYType Oil-Cooled Motorized Drum

TDY type oil-cooled motorized drum is widely used for general purpose in China. Its motor is made by the special motor producers,It’s not below national Y series standard at the same power level.For meeting the requirements of our customers,TDY type oil-cooled motorized drum will continue to be produced.

TDY Type parameter list

| Drum dia.D(mm) | Power P(kW) | Belt ) | Velocity of drum surface V(m/s) | Mass M (kg) | |||||||||||

| 0.25 | 0.32 | 0.4 | 0.5 | 0.63 | 0.8 | 1.0 | 1.25 | 1.6 | 2.0 | 2.5 | 3.15 | ||||

| Φ320 | 1.5/2.2/3 | 500/650/800/100 | △ | △ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | 130/140/160/170 | |||

| 4/5.5 | 500/650/800/1000 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | 170/180/200/220 | ||||||

| Φ400 | 2.2/3 | 500/650/800/100 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | 248/262/270/295 | ||

| 4 | 500/650/800/1000 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | 253/267/277/300 | ||||

| 5.5/7.5 | 650/800/100 | ○ | ○ | ○ | ○ | ○ | ○ | 273/287/297/320 | |||||||

| 11 | 800/1000 | ○ | ○ | ○ | ○ | 317/340 | |||||||||

| Φ500 | 2.2/3 | 500/650/800/1000 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |||

| 4/5.5 | 500/650/800/1000 | △ | △ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |||

| 7.5/11 | 650/800/1000/1200 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |||||

| 15/18.5 | 800/1000/1200 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||||

| 22 | 800/1000/1200 | ○ | ○ | ○ | ○ | ○ | |||||||||

TDY Type parameter list

| D | B | A | L | L1 | t | H | C | M | N | P | Q | H | DS |

| Φ320 | 500 | 850 | 600 | 920 | 115 | 120 | 125 | 70 | - | 340 | 280 | 35 | Φ27 |

| 650 | 1000 | 1070 | 1070 | ||||||||||

| 800 | 1300 | 1570 | 1570 | ||||||||||

| 1000 | 1500 | 1220 | 1220 | ||||||||||

| Φ400 | 500 | 850 | 600 | 940 | 1150 | 120 | 125 | 90 | - | 340 | 280 | 35 | Φ27 |

| 650 | 1000 | 1070 | 1090 | ||||||||||

| 800 | 1300 | 1570 | 1240 | ||||||||||

| 1000 | 1500 | 1220 | 1590 | ||||||||||

| Φ500 | 500 | 850 | 600 | 960 | 115 | 100 | 145 | 70 | - | 340 | 280 | 35 | Φ27 |

| 620 | |||||||||||||

| 650 | 1000 | 750 | 1120 | 120 | 90 | ||||||||

| 800 | 1300 | 950 | 1420 | ||||||||||

| 1000 | 1500 | 1150 | 1620 | ||||||||||

| 1200 | 1750 | 1400 | 1870 | ||||||||||

| Φ630

Φ800 |

650 | 1000 | 750 | 1120 | 115 | 120 | 175 | 90 | - | 340 | 280 | 35 | Φ27 |

| 800 | 1300 | 950 | 1430 | 140 | 130 | 80 | 400 | 330 | 35 | Φ27 | |||

| 1000 | 1500 | 1150 | 1630 | ||||||||||

| 1200 | 1750 | 1400 | 1900 | 160 | 180 | 150 | 90 | 440 | 360 | 50 | Φ34 | ||

| 1400 | 2000 | 1600 | 2150 | ||||||||||

| 1600 | 2200 | 1800 | 2350 |